Graphene has been the focal point for many research projects in recent years. It has proved to be one the most diverse materials known to man and recently a team of researchers from Northwestern Engineering have stumbled upon a method of creating graphene ink while trying to discover a new method producing graphene.

Their aim was to preserve the conductivity of graphene by adding low-cost solvents such as ethanol and ethyl cellulose. They managed to create high concentration of graphene flakes and then realized this could be made into ink with further use of solvents.

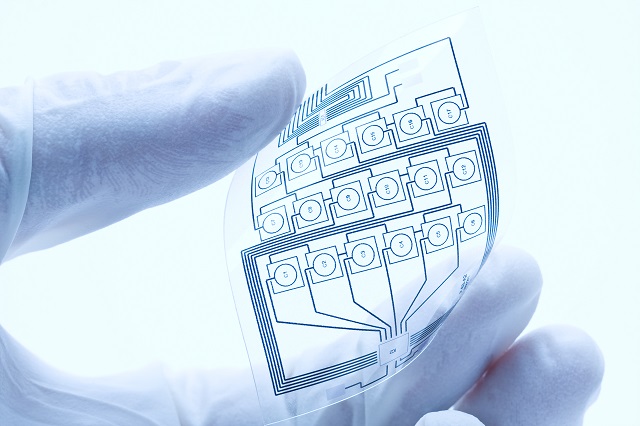

The new material displayed properties such as good electric conductivity, high flexibility and optical transparency. Developers then started looking at how graphene ink could be used to create wearable / foldable technology.

To prove its versatility, a research team from Cambridge University printed a piano circuit board onto fabric using conductive graphene ink as well as a digital display onto a bendable plastic substrate.

The team have also proposed that this concept could be used for printing health monitoring circuit boards onto clothing.

Although widespread research is being conducted, many of the graphene ink related concepts are still in the lab. For instance, the Center for Graphene Science at the University of Exeter is working on printing circuits on to smart t-shirts, solar panel films and interactive smart-screens using the ink.

Looking Forward

Researchers are beginning to see the true potential of this amazing material. US-based company, Vorbeck has ventured into making graphene ink products a reality. They supply a range of VOR-INK™ products such as gravure, screen, and flexo that can be applied to using various printing methods onto specific substrates.

Other possible applications include:

Printing 3D circuit boards

Coatings and smart packaging

Heat sinks and sensors

Radio-frequency identification (RFID)

Plastic electronics, LCDs and flexible displays

Catalytic devices and OLED devices

E-Paper and transparent electrodes

Thin film photovoltaics

Electrochemical devices

Graphene phone displays that can be printed on human body

Researchers have proved that graphene ink can be printed in multiple layers with a thickness of just 14 nm, so as to create accurate patterns.

Graphene ink could be used to manufacture foldable electronic devices in the foreseeable future. It may also may help in the development of new wearable technology and offer a whole new generation of technology to customers.