People rely on a highly tuned sense of touch to manipulate objects, but injuries to the skin and the simple act of wearing gloves can impair this ability. Surgeons, for example, find that gloves decrease their ability to manipulate soft tissues. Astronauts are also hampered by heavy spacesuits and find it difficult to work with equipment while wearing heavy gloves.

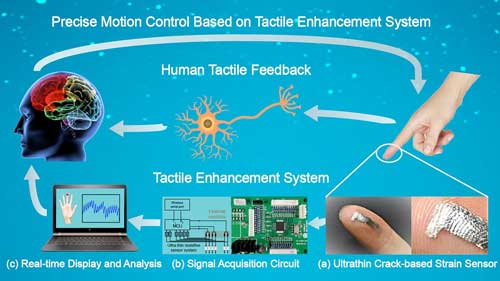

In this week’s issue of Applied Physics Reviews (“Visually aided tactile enhancement system based on ultrathin highly sensitive crack-based strain sensors”), scientists report the development of a new tactile-enhancement system based on a highly sensitive sensor. The sensor has remarkable sensitivity, allowing the wearer to detect the light brush of a feather, the touch of a flower petal, water droplets falling on a finger and even a wire too small to be seen.

The crack-based sensor used in this device was inspired by a spider’s slit organ, an idea first proposed by other researchers. This pattern of cracks in the exoskeleton allows the spider to detect small movements. In the same way, the ultrathin crack-based strain sensor, or UCSS, uses cracks formed in a thin layer of electrically conductive silver.

The UCSS is fabricated from several layers of flexible polymer film coated with silver. The entire system is draped and stretched over a curved surface, causing the silver to crack, and generating parallel channels that conduct electricity and are sensitive to movement.

The investigators found thinner layers of both the flexible film and the silver yielded sensors with higher sensitivity, while thicker ones exhibited a larger sensing range. To achieve a balance of these two effects, UCSSs with 15-micron thick polymer layers and 37-nanometer thick silver layers were the best choice.

The investigators also designed a visually aided tactile enhancement system, VATES, by connecting one or more UCSSs to a signal acquisition unit and visual readout device. They attached UCSSs to gloves, either on the fingertips or on the back of the hand, producing a type of electronic skin, or e-skin. Tiny movements, as small as a person’s pulse moving the tip of a finger, could be monitored.

The investigators suggest UCSSs could be used in a variety of ways: as highly sensitive electronic whiskers, which can be used to map wind flow patterns; as wearable sensors for heartbeat and pulse detection; or as sensors on prosthetics to enhance the sense of touch.

They also demonstrated their use when applied to various parts of the body. UCSSs were able to detect movement due to smiling, frowning and eye blinking.

Co-author Caofeng Pan said, “These results demonstrate the wide applications of our ultrathin strain sensor in e-skin and human-machine interfaces.”

Source: American Institute of Physics

Virtual reality (VR) and augmented reality (AR) are some of the hottest multidisciplinary technology trends right now, integrating computer, various sensor, graphic image, communication, measurement and control multimedia, artificial intelligence, and other technologies.

Read moreGene-infused nanoparticles used for combating disease work better when they include plant-based relatives of cholesterol because their shape and structure help the genes get where they need to be inside cells.

Read more