Product innovation

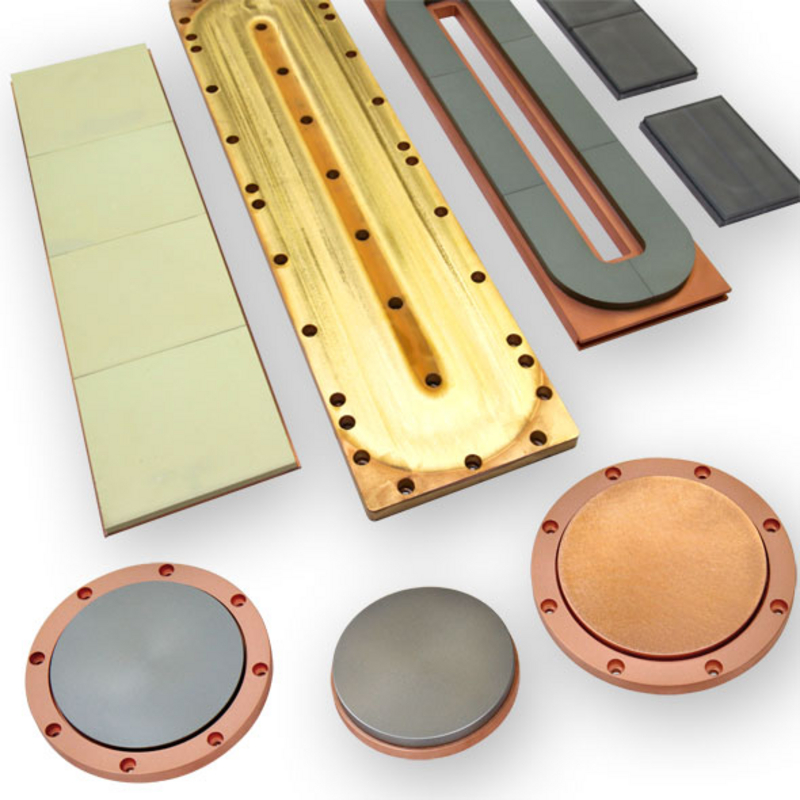

Codex International’s new EPC © (Enhanced Process Control) process is an innovative manufacturing process that improves target performance, durability and deposit homogeneity.

Codex International has developed a new technology for manufacturing EPC© sputtering targets that optimizes the flow of materials and significantly improves their sputtering performance.

Our EPC© process allows a better control of crystalline orientations and grain size (especially for ferromagnetic materials). Sputtering targets manufactured using Codex International’s EPC© process have the following competitive advantages

– Minimize magnetic shunting

– Stabilize the plasma

– Improve thin film uniformity

– Increase thin film deposition rates and reduce cycle times.

Discover Also

Creating defect-free sheets of Graphene is said to be one of the main ‘hurdles’ in the search for wide scale commercialization of the material… but why is it so important to form large defect free sheets?

Graphene has received an astonishing amount of interest these past few years, so much so that now it is commonly referred to as the miracle material that’s predicted to revolutionize the 21st century.

Scientists at Tokyo Institute of Technology have shown that copper oxide particles on the sub-nanoscale are more powerful catalysts than those on the nanoscale. These subnanoparticles can also catalyze the oxidation reactions of aromatic hydrocarbons far more effectively than catalysts currently used in industry.

Read more