In the background material to his Nobel Prize talk in 2010, Prof. Geim illustrated the strength of graphene with his now famous cat hammock example (taken from: Scientific Background on the Nobel Prize in Physics 2010 – Graphene): The unit hexagonal cell of graphene contains two carbon atoms and has an area of 0.052 nm2. That translates into a density of 0.77 mg/m2. A hypothetical hammock measuring one square meter made from graphene would thus weigh 0.77 mg.

In this 1 m2 graphene hammock tied between two trees you could place a weight of 4 kg before it would break. It should therefore be possible to make an almost invisible hammock out of single-layer graphene that could hold a cat without breaking. The hammock would weigh less that than 1 mg, corresponding to the weight of one of the cat’s whiskers.

“Though very engaging, this picture skips the fact that so far nobody has been able to produce such a large contiguous piece of graphene without grains and stitching,” Slava V. Rotkin, Frontier Professor of Engineering Science & Mechanics and Professor of Biomedical Engineering at the Materials Research Institute and Department of Engineering Science & Mechanics, The Pennsylvania State University, tells Nanowerk. “Our work shows that a method exists to produce such a perfect hexagonal net of atoms without stitching faults. We found that Nature organizes itself in a way to promote, under certain conditions, ‘knitting’ such an ideal lattice.”

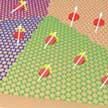

In their paper in Advanced Materials (“Large-Area Single-Crystal Graphene via Self-Organization at the Macroscale”), Rotkin and a team of international collaborators demonstrate that single-grain growth of graphene crystals can be achieved over a large, macroscale, area (the team used a 5×5 mm substrate).

Specifically, the team shows that graphene flakes, nucleated over a polycrystalline graphene film, synchronize during growth so as to ultimately yield a common crystal orientation at the macroscale.

The phenomenon of self-alignment of graphene grains during their growth, which the team discovered experimentally, has never been observed before – and at this time the scientists don’t have a good model for the underlying physics which leads to this effect.

In their experiments, the team found that graphene islands self-align over large areas; later they proved that it was not just a ‘large’ area – the whole sample got involved in this correlated growth.

They then performed a lot of detailed studies to prove the effect and understand the details.

“We had a unique group to get it done,” says Rotkin. “Prof. Mark Rümmeli at Suzhou University and Dr. Huy Ta Quang at IFW Dresden are masters of CVD synthesis and, at the same time, world-leading experts in high-quality electron microscopy – while I was responsible in our team for theory and optical characterization. In order to discover the effect, we had to combine methods that are rarely used together: optical Raman microscopy and DF-TEM of the same sample. The challenge was to verify the single atom-thick islands’ orientation over an enormously large area.”

“When I saw coherent orientation of the islands for the first time, this was amazing – similar to the order appearing in large flocks of birds,” Rotkin points out. “Of course we are now keen to uncover the physics behind this phenomenon.”

A new scattering Scanning Near-field Optical Microscope – a $1M piece of equipment has been acquired recently in Rotkin’s lab at Penn State. “This customized instrument is set for nanoscale optical characterization – which will be the best tool for such atomistic studies at a large scale.”

For instance, scientists want to determine the forces between grains just as they form during the synthesis phase.

In the past, single-grain growth of graphene has been achieved by other methods, but they all require expensive substrates or quite complicated technologies. Devising a robust and inexpensive growth technique for large-area crystals has direct technological consequences for producing high-quality graphene.

“In all modern electronic devices, that have already reached atomic size limit, the variability is a major concern,” says Rotkin. “If industry will be able to produce high-quality graphene, with no grains, no stacking faults, and no misorientation, this would make the ‘wonder-material’ acceptable for use in commercial products and even desirable for a large number of technologies – from RF electronics to flexible displays.”

Rotkin concludes on a more cautionary note that the tasks of scaling up this technique to wafer-scale, translating it to other 2D materials, and being able to achieve full control of the crystal orientation might well take several years of research.

By folding snippets of DNA into the shape of a five-pointed star using structural DNA nanotechnology, researchers have created a trap that captures Dengue virus as it floats in the bloodstream. Once sprung, the trap – which is non-toxic and is naturally cleared from the body – lights up. It’s the most sensitive test for the mosquito-borne diseases yet devised.

Read moreResearchers from the University of Rostock and Technion Haifa have created the first three-dimensional topological insulator for light. A judiciously placed screw dislocation allows optical signals to wind around the surface of a synthetic lattice while keeping it protected from scattering.

Their discovery has recently been published in the journal Nature (“Photonic topological insulator induced by a dislocation in three dimensions”).