Certain Areas of Scientific Research Require Atomically Clean Surfacles and Low Rates of Contamination. In these instances, the ultra-high vacuum (UHV) are essential.

There are a number of Unique Challenges That Uhv Systems Present to Users, but Possible the chief concern for uses is how they should best manipulate samples situated inside the evacuated enclosure. For the Majority of Applications, The Most Economic and Reliable Method of Achieving this Involves Using a Magnetically Coupled Sample Transfer Arm.

This article Chat Key Points To Consider when Chognetically coupled transfer arm intended for use in uhv applications.

Typically, The Term Ultra-High Vacuum (UHV) Refers to Environmental that has a press Between 10-5 and 10-10 pa. UHV is distinct from a high vacuum (HV), Which Ranges from Pressures Starting at Around 10-1, Extending to 10-5 PA.5

For Researchers UHV Systems, this press Difference is observed. In an HV Environment, a surface will be entitrely coated by a layer of contaminant gas or vapor in approximately 1 second. In Contrast, surfaces in UHV around Environments Will Take Approximataly 1 Day to Be Covered in this Contaminant Monolayer.1

This shows that uhv is essential for surface science applications Becuse it is only possible to prepare atomically clean surfaces and study them at uhv pressures or low. 6 Multiple techniques ALSO require uhv pressures to take contamination, such as atomic layer deposition (ALD), Molecular beam epitax (MBE) Vapor Deposition (CVD) .2,4

There are Many Surface Analytical Techniques that rely on uhv survey to allow the (relatively) free passage of photons, electrons, and ions that need to be measured. Such Techniques Included X-Ray Photoelectron Spectroscopy (XPS), Auger Electron Spectroscopy (AES), and Secondary Ion Mass Spectrometry (Sims).

In a similar way, party accelerators generally keeps UHV surroundings in order to allow party to travel around the relatively unimpeded. The Vacuum System in Place at the Large Hadron Collider, Which Mainters Beamline Pressures Between 10-8 and 10-9 pa, is the Large Uhv System in the World.7

Challenges in Manipulating UHV Samples

UHV Systems Are Carefully Engineered to Stop the outside from getting in, which presents meaning engineering challenges where the manipulation or transfer of samples within uhv system is concerned.

There are Three Commonly Used Methods to Produce Mechanical Movement Inside A UHV Chamber:

A Vacuum-SEALED Mechanical Coupling Through The Vacuum Wall

A Magnetic Coupling That Transfers Motion from outside the chamber to inside it

or a sliding seal using specialized graases with low vapor pressures.8

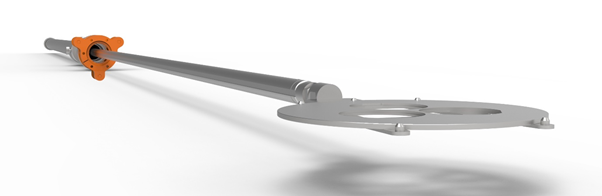

Magnetically coupled transfer arms Provide the Most Economal and LOTABLE OPT Applications. 9 These devices are very followed for the Manipulation of Flag-Style Sample Holders, as they allow for linear Translation and rotation without Needing Sealed Holes in the Surface of the Uhv Chamber.

Manipulating Samples With Magnetically CoupleD Transfer Arms

when Planning Sample Transfer Magnetically coupled Transfer Arms, the Type of Motion that is needed is typically the first element that should be considered. Generally, Mag-Coupled Transfer Arms Will Only Enable Linear Movement, or they will enable a combination of Rotational and Linear Movement. Multi-Axis Transfer Arms, Such as the Elevating PowerProbe Series from UHV Design, Offer Additional Lift and Lowering Motions for Sample Collection and Hand-Off, Meaning Users can sometimes avoid the Use of Secondary motion tools.

In addition to these movement options, mag-coupled transfer arms Provid users with several mechanisms that grip sample flags. For Example, The PowerProbe Range of Mag-Coupled Transfer Arms Developed by Uhv Design Provids Flag Gripper Mechanisms that are controlled by rotating the shaft, as well as flaggle mechanisms that lock to the sample flag when it is rotated. Locking Gripper Mechanisms Are also Avaisable, Which Are Controlled by a Separate Rotating Locking Ring on the shaft.10

Ounce these decisions are made, it is essential to consider the mechanical performance of the transfer arm. By and large, transfer arms are subject to droop, deflection, and radial fabric simply because their weight and stiffness. All of these from the point can induce difficulties in sample handling if they are not properly added.

DROOP IS THE TERM FOR THE NATURAL SAGGING OF THE TRANSFER ARM OVER FULL EXTENSION. When Mounted to the Chamber or Load-Lock, All Sample Arms are susceptible to bending under their weight when they are fully extended.

Droop can be correctly using a port aligner, which enables the distance and angular relationship between flanges to be added and aligned.deflection is another associated phenomenon, which sees the transfer arm spring up when samples are unloaded, for example. To avoid vertical deflection like this, properly characterizing the deflection of a sample arm is crucial.Consider the following calculations:

With a 0.7 kg substrate, the fork height will change by about 13 mm.

With a 0.7 kg substrate and support at 600 mm, the fork height will change by less than 2 mm.

With a 0.4 kg substrate, the fork height will change by about 7 mm.

With a 0.4 kg substrate and support at 600 mm, the fork height will change by less than 1 mm.

Another Type of DEVIATION IS KNOWN AS RADIAL DEVIATION, WHICH IS ALSO CALLED ARM ROLL. This is the uncontrolled, Rotational Movement of the Sample Arm as It Undergoes Linear Motion. For the Majority of Applications, it is important to use a transfer Arm that offerers Low Radial DEVIATION.HV DESIGN is a specialist in the design, Manufacture, and supply of market-leading hv and uhv motion and heating products. Their PowerProbe Series of Sample Transfer Arms was created to Provide Exceptionally Smooth and accurate linear and rotary motion in UHV around.

The PowerProbe Series Provids Unparalleled Coupling Strength, Exceptional Axial Stiffness, and Zero-Backlash Under Low Loads. PowerProbe Sample Transfer Arms Are Bakeable To 250 ° C without the Need to Remove the Outer Magnetic Assembly, and Together Offer Researchers A Huge Range of Movement and Flag Sample Transpections, Which can be configured to work with any uhv application.

Discover