The Rapid Development of Ultra-Thin Electronic Skins (E-Skins)-ALSO Called Epidermal Electronics or Electronic Tattoos-is Opening New Realms of possibility for flexible and Stretchable Monitoring Gadgets that Are Wearable Directly on the Skin. These e-skin Devices can be used for, Among Other Things, Prosthetics and Rehabilitation, Optogenics, Human-Machine Interfaces, Human-Competant Interaction in Gaming, and AS Diagnostic Tools in the Medical Field (Read More On This Topic in "Lab-on-Skin: Nanotechnology Electronics for Wearable health monitoring ”).

E-skins require equally thin and flexible press sensors with a large responsibility rage and high sensitivity. The Pressure-Sensitive Performance of Devices can usually be Evaluated via Several Basic Characteristics, in Terms of Durability/Stability, Response/Recovery Rate, Detection Range, and Sensitive Response, which Also Provide A Reference for the Functional Design of the Sensor. Among these characteristics, Detection Range and Sensitive Response Are Two Key Factors Affecting Sensor Property.

Researchers Now Report An Mxene-Based Approach to Designing the Sensing Material of E-Skins to Meet The Above Two Needs.

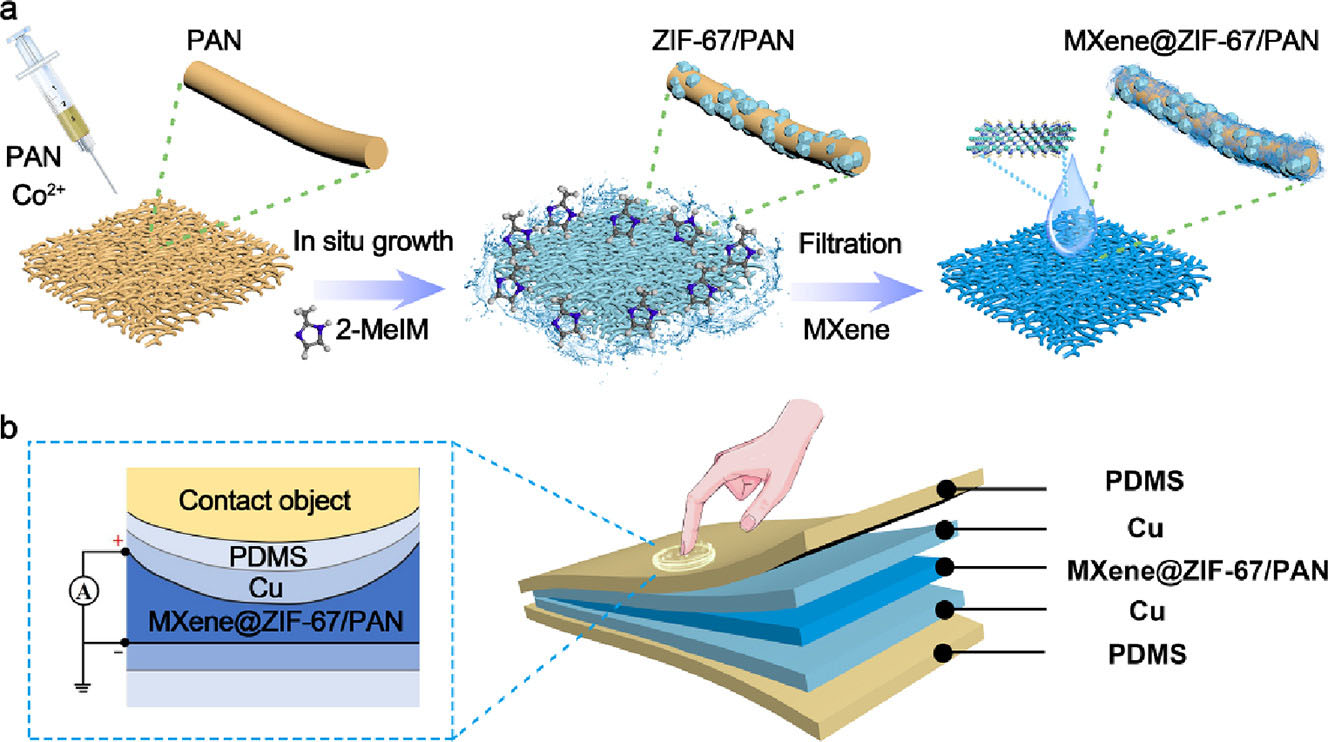

AS they report in ACS ACS Applied Materials & Interfaces ("Mxene/ZIF-67/Polyacrylonitrile (Pan) Nanofiber Film for Ultra-Sensitive Pressure Sensors"), they fabricated a flexible Sensor Pressure by Sandwiching A conductive mxene/ZIF-67/Pan Film Between Pdms and Copper Electrodes.

BENEFING FROM THE SPECIAL ROCH AND POROUS structure and 3D Stable conductive Network of the Nanofiber Film, The Researchers' Sensor is Able to Simultaneously Obtain A Wide Sensing Range (0−100 KPA) and High Sensitivity (62.8 KPA - 1) and Display A Robust Mechanical Stability (Over 10,000 Cycles), and Fast Response/Recovery Time (10/8 ms).

To fabricate their e-skin sensor, the team first flexible flexible nanofiber films with rough structures via in situ embedding of metal-organic framework (MOF) Particles on flexible pan nanofibers.

Incorporating Mxene Nanosheets Into these films results in a three-dimensional (3D) conductive network structure. As the Authors Point Out, The Unique Rough Structure of this Mxene/ZIF-67/Pan Film Allows for Better Connection of the Conductive Pathways when Force is Applied, which contributes to the Ultrahigh Sensitive Response and Broad Sensing Range of the Flexible Device.

The Authors concludes their report by noting that excellent sensing properies, coupled with encouraging benefits such as good biocompatibility and high flexibility, makes this sensor a competition for flexible and wearable health devices.

Discover