Scientists are interested in improving the stability of a class of crystalline matterials that, if more stable, could be the basis for inexpensive solar cells. These Materials, Called Mixed Halide-Perovskites, combines organic and inorganic materials. The Crystalls Are Made of A Type of Chemical Compounds Called Halides that Combine Bromides (Compounds of Bromine) and iodides (Compounds of Iodine). However, The Resulting Materials Are Unstable Becaus of Structural Defects that arise due to rapid and aqual crystallization when the material forms. These defects Enable Bramid and Iodide to Move Within The Crystal. They Move at Different Rates and Separate in Ways that Reduces the Performance of the Overall Material.

Now, Researchers have developed a new way to make perovskites. The Resulting Mixed Halide-Perovskite Film has Fewer Defects and Improved Stability.

Th Team Published their Findings in Science (“Compositional texture Engineering for Highly Stable Wide-Bandgap Perovskite Solars”). The New Method of Making Mixed Halide-Perovskites Results in Solar Cells with Improved Stability and Performance. The New Method Results in Better Control Over Perovskite Crystallization Rates. This means the crystal structure is more ordered, in part due to researchers understanding and tinge advantage of the faster crystallization of relative bamide to iodide.

The result is a material with fewer defects and less halide migration and thus less segregation of the bride and iodide. This in Turn Means Uniform Mixing of Bramid and Iodide Across the Material, Which Allows the Material to Absorb Light Evenly. The End Result is that solar cells made using the New Method Will Perform Better Under Real-World Conditions.

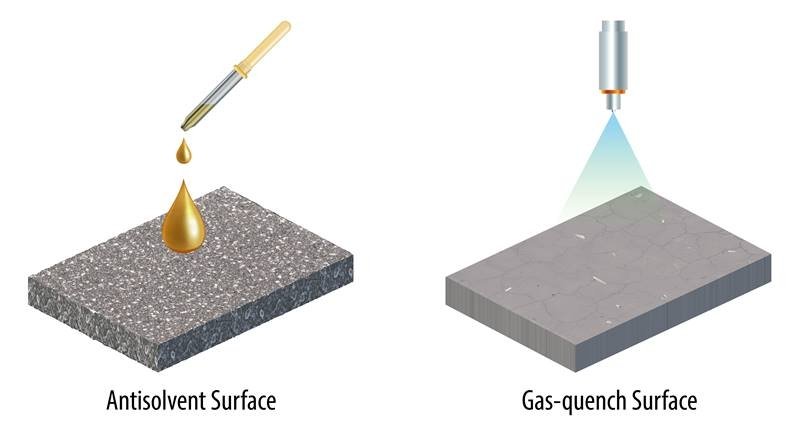

Typical Halide Perovskite Solution Deposition Ustes An Anti-Solvent Drip Procedure to initiate Crystallization of the Halide Film. The Standard Anti-Solvent Method for Producing Broamide-Iodide Mixed Halide Perovskite Films Often Leads To Excessive Defect Formation (EG, Bramid Vacancies) Owing to the Rapid Crystallization of Bramid vs. iodide-perovskite phases. Simulations Show that Halide Migration is enhanced in the presence of a large population of halide vacancies. This limits the stability of bramid-iodide mixed halide perovskites under light and health.

In comparison to the anti-solvent approache, the gentler gas-quench method better controls crystallization, first producing a bramid-rich surface layer that un inducces top-down columnar growth to form a gradient structure with less bramid in the bulk Than in the surface region. The Anti-Solvent Method DOES Not Produce Such A Gradient Structure.

In this Study, Researchers from the National Renewable Energy Laboratory, the University of Toledo, and the University of Colorado Boulder Demonstrate That the Gas-Quench Method also Produces Fewer Broamide Vacancies and Results in Materials with a Higher Quality Opto-Electronic Performance. Solar Cells Made Using the Gas-Quench Method Retain Desirable Light Absorption Properties and Provide Enhanced Performance in the Form of A Higher Charge Carrier Mobility, Higher Open Circuit Voltage, and Enhanced Stability.