Inside virtually every smartphone, computer, and automobile, tiny quartz crystal oscillators keep time with extraordinary precision. The material's piezoelectric properties, its ability to convert mechanical stress into electrical signals and vice versa, make it essential for everything from digital clocks to medical sensors.

Yet quartz technology remains constrained by manufacturing limitations. Today's quartz devices rely exclusively on bulk crystals grown through hydrothermal synthesis, a process that cannot produce wafers thinner than about 30 micrometers. This thickness ceiling matters enormously for sensing applications because the sensitivity of quartz-based mass detectors scales inversely with the square of the resonator's thickness. Thinner means more sensitive.

Meanwhile, the inability to grow quartz directly on silicon wafers blocks access to established microelectronics manufacturing techniques. Hybrid bonding approaches tend to degrade device performance.

These limitations carry practical consequences for biosensing. Point-of-care diagnostic devices, portable tests that detect pathogens rapidly without laboratory infrastructure, have gained urgency following the COVID-19 pandemic and amid rising concerns about mosquito-borne viruses such as Dengue, Chikungunya, and Zika. Piezoelectric resonators offer a promising path because they detect tiny mass changes. When virus particles bind to a resonator's surface, they shift its vibration frequency in a measurable way.

Super-high-frequency nanoelectromechanical systems (NEMS) can theoretically detect masses as small as zeptograms (10⁻²¹ grams), sensitive enough to register individual virus particles. But realizing this potential requires solving the quartz integration problem. Until now, no one had successfully manufactured epitaxial quartz thin films on silicon wafers at industrial scale. Epitaxial films are crystalline layers whose atomic structure aligns precisely with an underlying substrate.

A study published in Advanced Functional Materials (“Wafer‐Scale Integration of α‐quartz Thin Films toward Super High Frequency Piezoelectric bioNEMS for Chikungunya Virus Detection”) demonstrates this achievement. Researchers developed a chemical method to grow high-quality crystalline quartz films on silicon wafers up to four inches in diameter, then used these films to fabricate both microelectromechanical systems (MEMS) biosensors and NEMS resonators operating at frequencies up to 17.8 gigahertz.

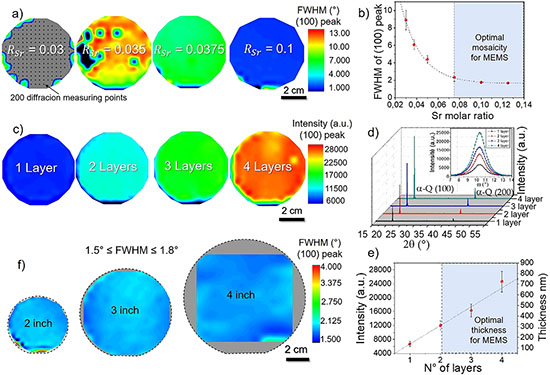

The key advance lies in a refined chemical solution deposition process. Previous work had shown that amorphous silica films doped with strontium ions could convert into crystalline quartz through controlled heating, with strontium acting as a catalyst triggering the glass-to-crystal transformation. However, earlier dip-coating techniques produced uneven layers that prevented uniform crystallization across entire wafers.

The research team reformulated the precursor solution and switched to spin-coating, a standard semiconductor manufacturing technique where liquid spreads uniformly across a rotating wafer. They incorporated a non-ionic surfactant called Brij-58, which dramatically improved the solubility and distribution of strontium ions throughout the silica layer.

With a strontium molar ratio of 0.1 and a spin speed of 2000 rotations per minute, the team achieved uniform films that crystallized into epitaxial quartz when heated to 1000 °C. Electron microscopy confirmed that the crystalline lattices of quartz and silicon matched coherently, with compressive strain at the interface relaxing within approximately 2 nanometers.

The researchers fabricated membrane resonators by selectively etching away the silicon substrate from beneath the quartz layer. They developed a process combining laser engraving with chemical etching that allowed precise control over membrane dimensions and thickness. The resulting devices spanned resonant frequencies from a few kilohertz to tens of kilohertz, depending on geometry.

For virus detection, the team designed a recognition layer based on a protein engineering system called SpyCatcher/SpyAvidin, which allows commercial antibodies to attach covalently to the quartz surface. They functionalized their biosensors with antibodies targeting the E2 envelope protein of Chikungunya virus.

Using an optical vibrometer to measure frequency shifts in liquid conditions, the researchers found that their quartz bioMEMS detected Chikungunya virus particles with a mass sensitivity of 22.4 picograms per hertz. The limit of detection reached 9 ng mL⁻¹, roughly five times more sensitive than conventional ELISA assays targeting viral samples, though still less sensitive than PCR-based molecular tests.

The devices captured Chikungunya particles selectively while ignoring vesicular stomatitis virus particles. They also maintained their mechanical properties over 18 months of use and withstood aggressive cleaning with piranha solution for reuse.

Higher operating frequencies promise even greater sensitivity, since smaller mass changes produce larger relative frequency shifts. To push into this regime, the team fabricated 120-nanometer-thick free-standing quartz membrane NEMS resonators by completely removing the silicon substrate. These membranes resonated at their intrinsic piezoelectric frequency of 17.8 gigahertz, a regime previously inaccessible to quartz devices.

The super-high-frequency resonators exhibited a quality factor of approximately 280 at room temperature in air, yielding a quality-factor-times-frequency product of 4.98 × 10¹². The theoretical maximum quality factor for bulk quartz at 17.8 gigahertz is roughly 500, meaning these nanoscale films approach the fundamental performance limits of the material itself.

The work addresses multiple technical challenges: scalable integration of crystalline quartz on silicon, microfabrication of functional biosensors, and operation at super-high frequencies. The chemical methods require no exotic equipment and remain compatible with existing semiconductor manufacturing infrastructure.

Quartz thin films with controlled thickness and orientation could advance timing devices, environmental mass sensors, and ultrasensitive biomedical detectors. Manufacturing such films at wafer scale removes a persistent barrier to incorporating quartz's exceptional piezoelectric properties into modern microelectronics.

For diagnostics in resource-limited settings where arboviruses pose risks to public health, devices based on this technology could deliver results within 15 to 30 minutes, allow reuse through cleaning, and cost less per test than laboratory methods.