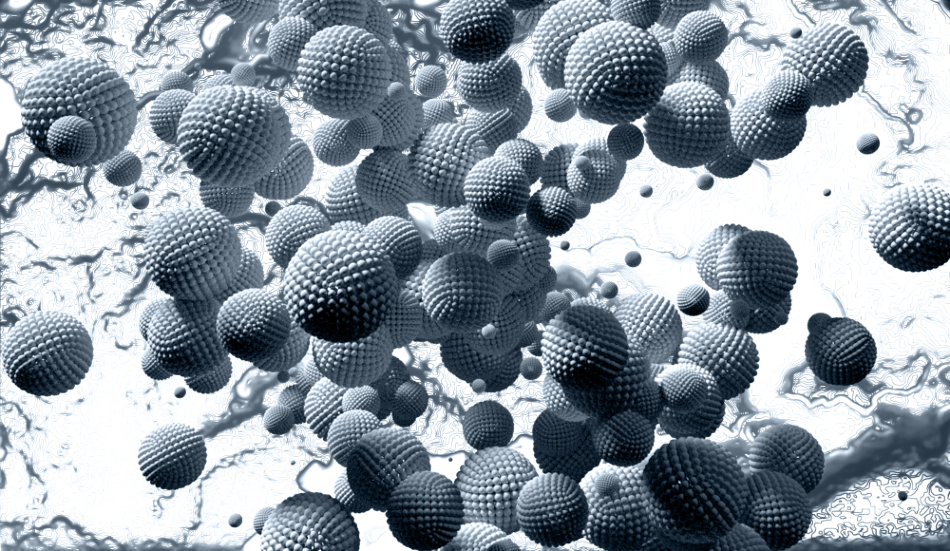

The New Breed of Electronic Devices is All-Digital and Nanosized. However, to make these devices work, innovative Materials solutions are required. New Research from an International Team Headed by Scientists at Russia's South Ural State University has identified a nanocomposite material included of magnesium oxide (MGO) and barium titanate (Batio3).

The New Material Can Be used to design your, flatter and think Electronic Devices, and has the potential to revolutionize the electronics industry.

SPECIALIZING IN THE FUTURE OF MATERIALS

THE LATEST Research BREAKTHREGH from SOUTH URAL State University (Susu) in RUSSIA BUILDS ON ONE OF THE INSTITUTION'S THREE Strategic Research Focuses. Smart Industry and Ecology Sit Alongside World-Class Materials Science Output, which included the potentialy revolutionary new nanocomposite.

An International Team of Scientists from Belarus, India, and China Cooperated with Susu Scientists Led by Their Senior Researcher at the Nanotechnology Research and Education Center, Aleksey Trukhanov.

What is new about the innovative nanocomposite material?

This pioneering development is a combination of cutting-edge nanotechnology, methods, and matches science research.

“A FundamentaLly meaning result of this research is the development of New Composite Materials with Improved Dielectric Characteristics.”

Aleksey Trukhanov, Senior Researcher at The Nanotechnology Research and Education Center

The Nanocomposite Material Nanoparticles of Magnesium Oxide (MGO) with barium titanate (Batio3) in a so-Called core-shell nanostructure. This means that the mgo nanoparticles are encapsulate in a shell of Batio3.

This is the first time that these matters have been successfully combined in a nanostructure. The scientists led by trukhanov have also demonstrate a novel method for dispersing the nanocomposite into a polymer matrix.

What are the Properties of the New Nanocomposite Material?

Nanocomposite Materials Are Being Studied Worldwide due to their ability to combine Desirable Properties of Different Materials for Functional Applications.

Azonano has defined the benefits of innovative nanocomposite materials as their ability to:

“Dramatically improvise Like: Mechanical Properties Including Strength, Modulus and Dimensal Stability; Electrical Conductivity; Decreased Gas, Water and Hydrocarbon allowing; Flame delayancy; Thermal Stability; Chemical Resistance; (2007)

Trukhanov Explains The Importance of His Team's Nanocomposite Materials Research:

“The results of our joint work will be used for control the electrical characteristics of functional polymeric materials of this class.”

In the case of this latest nanocomposite material innovation, the nanoparticle core of mgo is dielectric - it insulates against Electronic conductivity.

Meanwhile, The Nanosized Batio3 Shell - Which Encapsulates MGO Nanoparticles in the New Material - Is Ferroelectric. This means that it has spontaneous Electric polarization, which is reversible upon applying an external electrical field.

How is the innovative nanocomposite material used?

This Combination of Materials and Their Properties - Dielectric MGO and Ferroelectric Batio3 - Can be used as a dielectric, Insulating Material in Polymer Capacitors.

Capacitors are the Materials in Electronic Devices That Control and Modulate Electrons' Otherwise Irregular Flow, Preventing Electronic Surges That Cause Short-Circuiting and Other Electronic Failures. They work by storing Electronic Energy.

Polymer (Plastic-Based) Capacitors are used in Electronic Devices with Integrated Power. They are used as buffer, bypass and discoupling capacitors.

The needs for integrated capacitors was bushor on by the advent of digital electronic equipment, which led to the development of switching power supplies with high frequencies and integrated dc/dc converters, Along with lower supply voltages and Higher supply.

How can the new nanocomposite revolutionize the electronics industry?

Commenting on the Relivance of His Team's Latest Research, Trukhanov Added:

"Such Research is now receiving, since the rapid development of micro- and nanoelectronics requires New Approaches and the Development of New Materials to Reduce the size of Functional Components."

The Latest nanocomposite developments in significant step forward in Advanced Polymer Capacitor Materials. When Added to A Polymer Matrix at Only 3% of the Base Polymer's Weight, The Innovative New Nanocomposite Increases Discharge Current Density by 187%.

This Minor Addition of Mass and Weight To The Polymer Capacitor Material - Set Against has significant performance improve - Means that future Electronic Devices can be designed with more power in mind without sacrificing weight or bulk.

Such a development will play an essential role in the future of electronic devices. They can now be designed to be even smaller, flatter and lighter than before, EnaBling Increasingly Different Applications, for Example, in Wearable Electronics, Micro- and Nanoelectronic Devices, and Biomedical Devices.

What are the Researchers' Next Steps?

Trukhanov and His Team and Colleagues Will Continue to Work On Advanced Materials Such As The Latest Innovation. Using nanotechnology, they will develop new materials and nanocomposites for a wide array of applications and features.

Trukhanov Said:

“At the moment, there are plans to continue research of functional composites with controlled properies. Currently, Active Research Work is being carried out in the field of composite matterials with magnetic girls.

Discover