Skin-interfaced, wearable electronics have attracted significant attention due to their unique roles in preventative monitoring, diagnostic confirmation, and convenient therapeutic options. The ultimate application of these bio-integrated devices for practical and convenient applications hinges on the seamless integration of on-body sensors with wireless transmission modules.

Multifunctional on-body sensors can precisely and continuously monitor the health conditions of the human body, whereas wireless transmission modules can wirelessly power up the sensors and transmit the data generated from them to the cloud for the healthcare professionals.

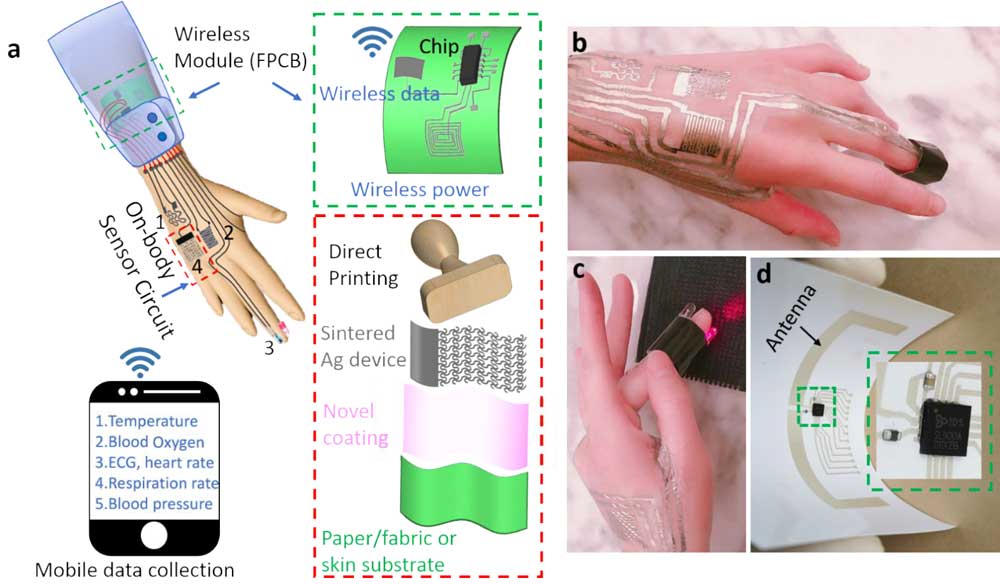

As a promising direction toward this class of integrated systems, soft body area sensor networks include on-body sensors for physiological signal monitoring and flexible printed circuit boards (FPCBs) for signal conditioning/readout and wireless transmission.

Realization of soft body area sensor networks currently linked on various sophisticated fabrication techniques ranging from lithography and transfer printing to direct printing, especially when stretchable sensors are separated from readout circuits.

Extensive research efforts have been devoted to exploring the integration of wearable electronics on paper/fabric or human skin. What has been missing so far, though, is a simple yet universal approach to fabricate all of the modules relevant to the soft body area sensor network, due to the challenging requirements of low-temperature processing on textured surfaces with easy removal capabilities.

Because conventional techniques in this field require expensive equipment and complicated procedures, and are increasing electronics waste, it is even more pressing to develop a new manufacturing technique to address all of these challenges.

An international research group from The Pennsylvania State University and Harbin Institute of Technology has done exactly that and is now reporting a simple yet universally applicable manufacturing technique for skin-interfaced sensors.

“One of the core innovations in our work is the design and demonstration of a novel sintering aid layer to enable direct printing and room-temperature sintering of various metal inks for constructing paper-/fabric-based FPCBs and on-body sensors,” Huanyu Cheng, an Assistant Professor of Engineering Science and Mechanics at Penn State's Materials Research Institute, tells Nanowerk. “This method allows metal nanoparticles to be sintered at low or even room temperatures, as compared to several hundreds of degrees Celsius in alternative approaches. »

The team's fabrication scheme relies on a sintering aid layer consisting of an adhesive polyvinyl alcohol (PVA) paste and nanoadditives (eg, TiO2 or CaCO3, among others).

They explain that previously published literature indicates that the sintering temperature of silver nanoparticles is reduced from 180 °C to 120 °C when the silver nanoparticles ink is sintered on the high-temperature-resistant paper that includes TiO2 as the main component:

“Therefore, we started our study by choosing TiO2 additive because it contributes to the reduced sintering temperature from charge neutralization to decrease the activation energy for enhanced sintering. Because cationic groups are needed for charge neutralization, we chose several other metallic oxides (Al2O3, MgO), salts (CaCO3, BaTiO3), and metal (Cu) as the additives to demonstrate the concept. By using the CaCO3 additive, the sintering temperature is further reduced to room temperature. »

“We attribute the reduced sintering temperature of silver nanoparticles with the use of the sintering aid layer to the increased grain boundary diffusion coefficient from charge neutralization, which is revealed by the experiment and phase-field simulations,” Cheng explains. “The sintering aid layer also reduces the surface roughness of various substrates to allow printing of an ultrathin layer of metal patterns with improved electromechanical performance against various mechanical deformations such as bending or folding. »

The researchers applied their fabrication scheme to enable skin-printed sensors for physiological signal monitoring, as well as paper-/fabric-based FPCBs for signal conditioning/readout and wireless transmission.

To illustrate a system-level example of their technique, they integrated various on-body sensors with an FPCB, as illustrated below.

The electronic system consists of sensors – directly printed on various locations of the human body – for vital signal measurements, commercial off-the-shelf chips for extended data collecting and processing, wireless data and power transmission modules, and paper/fabric-based FPCBs for system integration.

“We demonstrated that our high-performance skin-printed sensors could precisely and continuously capture temperature, humidity or local moisture change, blood oxygen saturation, electrophysiological signals such as electrocardiogram and electromyography, among others,” Cheng notes. “With enhanced signal quality and improved performance over their commercial counterparts, these skin-printed sensors together with other expanded modules provide the repertoire of wearable electronics for health monitoring. »

“Additionally, and highly relevant at the moment” he adds, “this system with modules of on-body sensors for physiological signal monitoring and wireless transmission can be applied to signal the progression and severity in COVID-19 patients. »

When large-scale adoption of this kind of wearable devices becomes part of our everyday lives, removal and environmentally compatible disposal become an issue. To that end, the researchers demonstrated that washing hands in warm water flow conveniently removes the device from the skin.

Furthermore, the materials exploited in the device system are biocompatible with minimal toxicity, which enables their use for green electronics, biointegrated electronics, or even implantable devices.

Cheng and his collaborators are now interested in applying this multifunctional, wearable sensing technology for diagnostic confirmation and timely treatments for cardiopulmonary diseases, including COVID-19, pneumonia, and fibrotic lung diseases.

They point out that, with excellent electromechanical and underwater performance, this sensing technology can also be used to track and monitor marine mammals.

“Excellent underwater performance with hermetic sealing seems to be a conflicting requirement from the need for a gas and water permeable device for long-term comfortable wear,” Cheng notes. “However, we are exploring the novel sintering layer in a porous structure with selective encapsulation to address this challenge. This design can be further combined with the demonstrated stable device performance after soaking in water. »

This present work is just one example of the central focus of this research group, which is on self-powered, wireless, multifunctional systems manufactured with low-cost technologies.

For self-powered devices, one of their projects focuses on stretchable rectennas for harvesting ambient RF energies for charging batteries or powering electronics. The multifunctional aspect also leads them to work on stretchable gas sensors for detecting gaseous biomarkers from the human body and exposed environment.

Another project involves alternative low-cost fabrication methods that enable direct fabrication of biodegradable and long-lasting sensors on 3D curvilinear freeform surfaces.

A logical extension of these various work areas includes the combination of wearable devices with big data analysis for future health informatics.

“The interdisciplinary nature of these diverse future directions calls for the joint efforts between clinicians and engineers with diverse backgrounds to help facilitate the rapid development in this burgeoning field,” Cheng concludes.